Chemical Resistant Laminate

In the food industry, chemical resistant laminate is widely used due to their excellent physical-chemical properties and food safety characteristics. The surface is treated with special technology, featuring antibacterial and anti-permeation capabilities, which can effectively inhibit bacterial growth and prevent microbial contamination during food processing. Meanwhile, these laminate is resistant to corrosion from chemicals such as acids, alkalis, and salts, withstanding long-term erosion from detergents and disinfectants to ensure the material remains stable without releasing harmful substances, complying with food contact material safety standards. Additionally, their dense structure and easy-cleaning property, combined with a seamless design, reduce dirt accumulation and the risk of cross-contamination. They are commonly applied to operating tables, walls, equipment cabinets, and other areas in food processing workshops. Their environmental friendliness and weather resistance also meet the strict requirements of food production environments, providing reliable hardware guarantees for food safety.

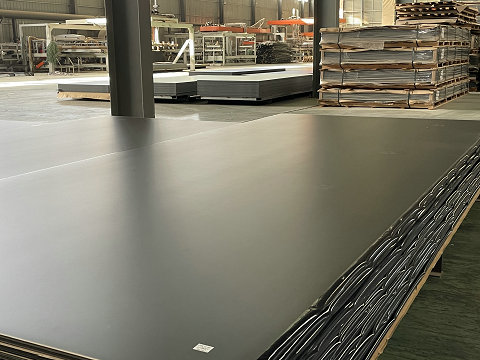

We are professional suppliers of chemical resistant laminate, specializing in wholesaling phenolic resin boards to the international market. It is a highly practical and sought – after material across multiple sectors, thanks to its remarkable ability to endure exposure to a plethora of chemicals. Its wide – ranging applications stem from its unique combination of durability, chemical resistance, and ease of maintenance.These laminates are widely applied in numerous fields. In laboratories, they can be use for workbench surfaces, withstanding the erosion of various acid – base reagents and ensuring the long – term stable use of the surfaces. In the pharmaceutical industry, such laminates that meet cleanroom standards can utilized for walls and cabinets, preventing the corrosion of chemicals during the drug production process and maintaining a clean environment.

Phenolic resin countertops

Grey epoxy countertops

Epoxy resin sinks

Laminate specifications

| Feature | Chemical resistance |

| Application | Phenolic resin countertop |

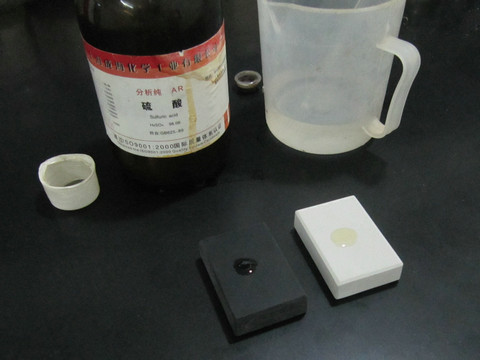

| Chemical resistance | SEFA3-2010 |

| Material | Phenolic resin |

| Type | Sheets |

| Color | Black,grey,white |

| Size (foot) | 5×12 |

| Size (mm) | 1525×3660 |

| Thickness(mm) | 12.7 16, 19, 25 |

| Surface finish | Matt |

| Density | 1.51 |

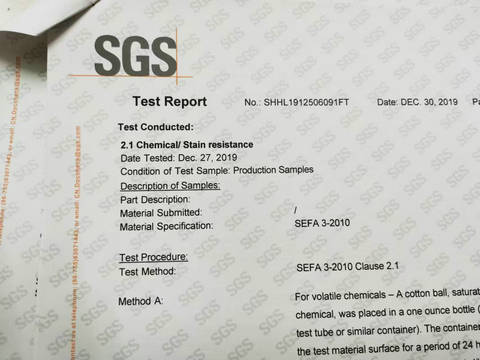

| Certificate | SGS |

| Mini order | 30 |

School lab countertops

Chemical resistant countertops fabrication

Chemical resistance

Certificate

Export shipping

Professional chemical resistant sheets supplier