Lab ceramic worktops

Lab Ceramic worktops offer many benefits for laboratory furniture. They resist chemicals, meet hygiene needs, last long, and can be customized. These make them practical and reliable for many lab settings. Whether in research labs, schools, or industrial facilities, lab ceramic countertops are a valuable investment. They improve lab efficiency, safety, and longevit

Feature

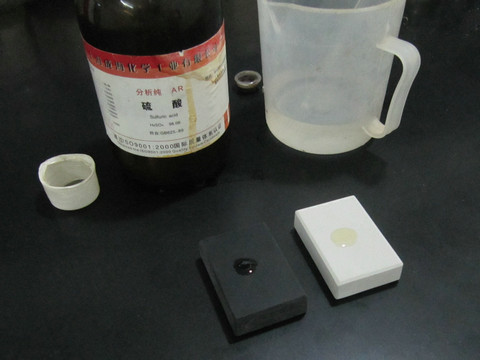

- Lab ceramic worktops resistance to common laboratory chemicals : it stand strong against corrosive acids like sulfuric acid, strong bases like sodium hydroxide, and harsh solvents. They do not break down or get damaged. Even when these chemicals touch them for a long time, they stay strong. For example, in a chemistry lab where people often do acid-base titrations, concentrated hydrochloric acid or potassium hydroxide might spill by accident. These spills do not stain, pit, or wear away ceramic worktops. This is very important for keeping the work surface usable.

- Inert surface that minimizes reactions with test samples: Ceramic is inert. This means it does not react with the test samples on the countertop. This is critical in analytical labs. Even a small contamination or chemical reaction can change experiment results there. Whether dealing with sensitive biological samples or reactive chemicals, the ceramic surface stays neutral. It keeps samples pure and accurate.

- Reduced risk of contamination compared to porous materials: Porous materials like wood or some stones have small holes. Ceramic worktops do not. Their surface is non-porous. Liquids, gases, and microorganisms cannot seep into them. This lowers the risk of cross-contamination between different experiments or samples. In microbiology labs, keeping things sterile is key. This feature is very valuable here. It stops unwanted bacteria or fungi from growing and spreading in the countertop.

Strong chemical resistance

Light blue ceramic countertops in chemical laboratory

Ceramic worktops fabrication

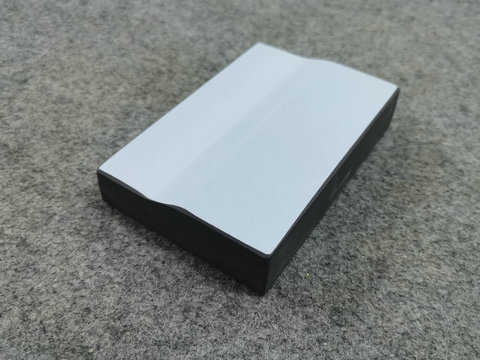

Marine edge lab ceramic boards

A professional lab ceramic worktops supplier

Looking for more

Youtube

Laboratory epoxy resin slabs

Epoxy resin lab countertops

Epoxy resin sinks

Lab ceramic countertops