Pros and Cons of Phenolic Countertops

The pros and cons of phenolic countertops are very obvious, and are summarized as follows:

Pros:

- High Cost-Effectiveness: Priced at only 60%-70% of epoxy countertops, they are ideal for budget-constrained settings like educational institutions and small-to-medium labs, with low long-term maintenance costs.

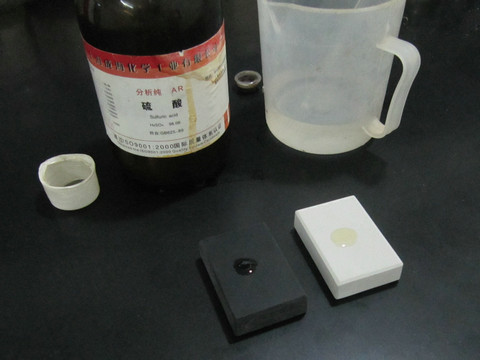

- Basic Corrosion Resistance: Resistant to dilute acids (e.g., 10% hydrochloric acid), weak alkalis (e.g., sodium carbonate solutions), and common reagents like alcohol and acetone, suitable for basic chemistry experiments.

- Balanced Physical Performance: With a hardness of HB grade, they offer better impact resistance than wooden countertops, capable of withstanding falls of objects under 20 kg without easy cracking or denting.

- Easy Installation and Versatility: Lightweight (approximately 70 kg/m²) for convenient handling and installation; available in various colors (e.g., dark gray, light blue) to match lab decor.

Cons:

- Limited Extreme Environment Resistance: Not suitable for concentrated acids (e.g., 98% sulfuric acid) or strong oxidizers (e.g., aqua regia), which can cause discoloration or bulging; long-term temperature tolerance below 120°C, with direct open flames causing carbonization.

- Hygienic Limitations: Micro-porous surfaces (pore size ~0.1-0.3 μm) may retain liquids, potentially fostering bacterial growth if not thoroughly cleaned, making them unsuitable for high-level biosafety labs.

- Aesthetic Durability Issues: Prolonged friction can wear the matte surface layer, leading to scratches that affect visual neatness and requiring regular polishing.

- Environmental Concerns: Some low-cost products use formaldehyde-containing phenolic resins, which may release harmful substances at high temperatures; prioritize brands with CE, UL, or other environmental certifications.

Phenolic countertops are a practical choice for basic labs, especially in educational settings. However, for high-precision research, highly corrosive environments, or sterile requirements, professional materials like epoxy resin or stainless steel are preferred.

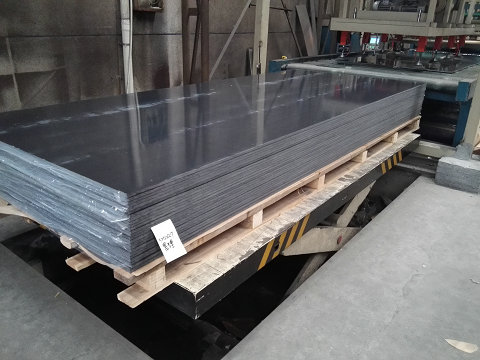

Phenolic resin countertops

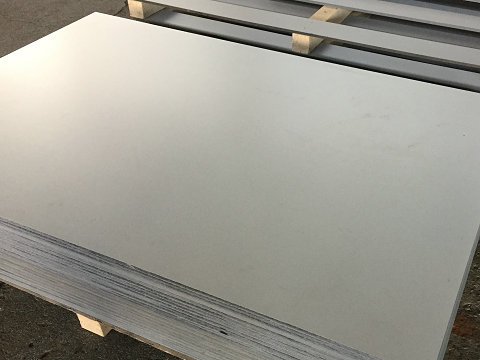

Grey epoxy countertops

Epoxy resin sinks

phenolic sheets Specification

| Name | Pros and Cons of Phenolic Countertops |

|---|---|

| Feature | Cost performance ratio |

| Material | Phenolic resin |

| Size | 6×12 =1525×3660 |

| Thickness | 12.7,16,19,25 |

| Color | Black, Light Grey, Green |

| Surface finish | Matt |

| Density | 1.51 |

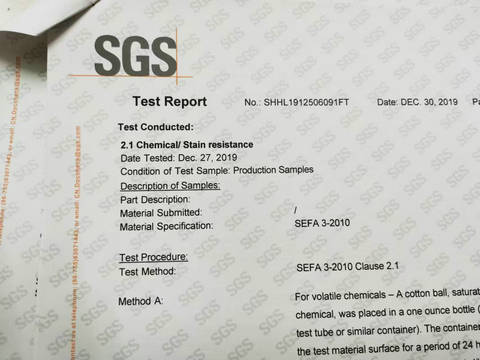

| SGS certificate | SEFA3-2010 |

| Mini order | 30 |

Phenolic resin boards

chemical resistance

SGS cretificate

Phenolic countertops fabrications

Shipping

Professional phenolic countertops supplier