Chemical resistant HPL

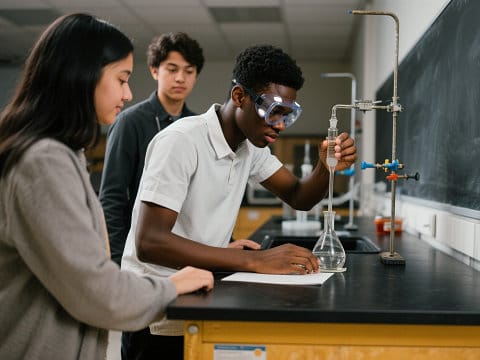

Chemical resistant HPL , often based on phenolic resin and reinforcing fibers, is a staple in middle school chemical labs. It boasts excellent resistance to organic solvents, acids, alkalis, and chemical spills—vital for lab environments with frequent reagent use.

Widely applied as workbench tops, fume hood surfaces and cabinet panels, it is non-flammable, complying with lab safety standards. Unlike wooden or plastic alternatives, it maintains structural stability under harsh reagents and -20℃ to 120℃ temperature fluctuations, ensuring durability.

Easy to clean and stain-resistant, it prevents cross-contamination. Though costly initially, its longevity and low maintenance make it cost-effective. It balances safety and practicality, becoming a reliable choice for labs prioritizing safety and sustainability.

The Economic Application of HPL in Middle School Laboratories

Overview of HPL’s Adaptability and Economic Advantages

High-Pressure Laminate HPL has become an ideal material for the renovation and reconstruction of middle school laboratories due to its excellent cost-effectiveness and adaptability. Generally, middle school laboratories have limited budgetary constraints and need to balance safety, durability, and ease of maintenance in use. HPL perfectly meets these requirements, with its economic advantages prominently reflected throughout the entire cycle of purchase, construction, and operation and maintenance,thereby fully aligning with the core demand of rational management of middle school educational funds.

Economic Advantages of HPL in Laboratory Countertops

As the core area of a laboratory, countertops pose high demands on material performance.

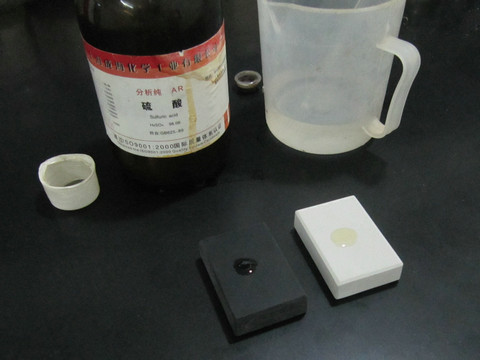

Chemical resistant HPL’s characteristics of acid and alkali resistance, impact resistance, and easy cleaning enable it to cope with daily scenarios such as chemical reagent spills, biological specimen processing, and experimental instrument placement.In comparison with high-end countertop materials like epoxy resin and stainless steel, the unit price of HPL is only 1/3 to 1/2 of the former, significantly reducing the initial purchase cost.

Meanwhile, its construction process is simple, requiring no specialized or complex equipment, and can be laid by ordinary construction teams, further effectively saving labor costs. Middle school laboratory countertops have high utilization rates but moderate experimental intensity, and HPL has a service life of 8 to 10 years, far exceeding that of perishable materials such as ordinary wood panels and ceramic tiles, which reduces repeated expenditures caused by frequent replacements and boasts remarkable long-term comprehensive cost advantages.

Chemical resistant HPL Application in Cabinets, Partitions and Auxiliary Facilities

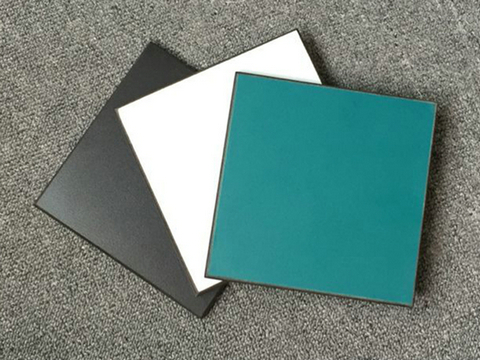

Beyond countertops, HPL also shows obvious economic value in the production of experimental cabinets, partitions, and auxiliary facilities, as it can directly replace traditional materials such as solid wood and medium-density fiberboard (MDF). The humid environment of laboratories easily causes mold and deformation of traditional panels, whereas HPL has excellent waterproof and moisture-proof performance, eliminating the need for additional anti-corrosion and moisture-proof treatments and saving auxiliary material and process costs. In addition, HPL comes in a wide range of colors and specifications, and can be cut and spliced on demand according to the functional division of laboratories. It does not require customized special panels, which not only meets the usage needs of different areas but also shortens the processing and construction cycles, consequently reducing indirect costs caused by idle venues. It is particularly suitable for the simultaneous renovation of multiple laboratories.

Environmental Protection and Comprehensive Economic Benefits

Furthermore, environmental protection and subsequent disposal costs are also taken into account in economic considerations. Waste HPL can be recycled and reprocessed into secondary panels for the production of laboratory auxiliary facilities, which not only conforms to the concept of green campus construction but also reduces environmental treatment costs. In summary, on the premise of meeting the safety standards for middle school laboratories, HPL achieves full-cycle cost control from initial investment to long-term operation and maintenance, effectively balancing practicality and economy. It can help middle schools efficiently build standardized and durable laboratory environments within limited funds.

HPL specifications

| Chemical resistant HPL | High cost effective |

|---|---|

| Application | Middle school, high school |

| Chemical resistance | SEFA3-2010 |

| Material | Phenolic resin |

| Color | Black,Grey,White |

| Size (foot) | 5×12 |

| Size (mm) | 1525×3660 |

| Thickness(mm) | 12.7,16,19,25 |

| Surface finish | Matt |

| Density | 1.5 |

| Certificate | SGS |

| Mini order | 30 |

Chemical resistant HPL machine

Chemical resistant testing

Certifications

Stock chemical resistant HPL sheets

HPL sheets loading

A Professional chemical resistant HPL supplier