Chemical Resistant Laminate

Chemical resistant laminate is a high-performance material tailored for laboratory environments. It boasts exceptional resistance to acids, alkalis, solvents and corrosive reagents, effectively preventing surface discoloration, swelling or degradation. With a dense, non-porous surface, it avoids chemical residue accumulation and is easy to wipe clean, meeting strict lab hygiene standards.

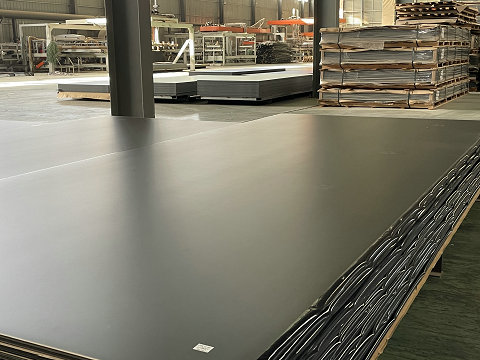

The material offers customizable sizes and thicknesses to fit various lab furniture layouts, while its wear-resistant and impact-resistant properties ensure long-term reliability. Lightweight yet durable, it simplifies installation and reduces maintenance costs, widely applied in chemical analysis, research labs and educational institutions.

Safeguarding Laboratory furniture

Essentially, chemical resistant laminate is the core material for ensuring the safety of laboratory furniture. With its outstanding comprehensive performance, it has become the first choice for key areas such as laboratory workbenches and cabinet bodies, thereby building the first line of defense for physics and chemistry experiments. Notably, compared with ordinary boards, chemical resistant laminate specifically address high-frequency risks in experimental scenarios, while widely adapting to various laboratory furniture for teaching and scientific research. They eliminate hidden dangers such as reagent corrosion and high-temperature damage from the source, thus creating a safe and controllable experimental environment for teachers, students and researchers.

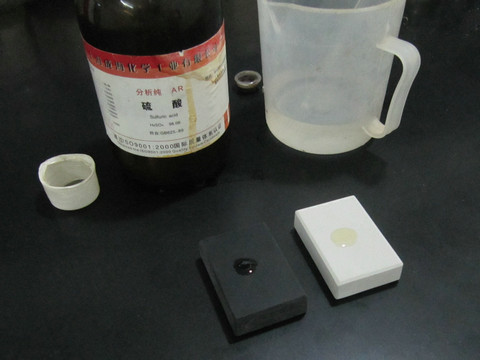

Specifically, its core advantage lies in super strong corrosion resistance, which can easily resist the erosion of strong acids and alkalis such as sulfuric acid and sodium hydroxide, as well as organic solvents such as ethanol and acetone. For instance, even in case of accidental reagent spillage, it can avoid leakage risks caused by material damage. At the same time, it has excellent high-temperature resistance and flame retardancy, capable of withstanding short-term high temperatures within 200℃. It remains stable when exposed to scenarios such as alcohol lamp baking and high-temperature instrument placement. Moreover, its surface is dense and smooth, easy to clean without residue, further eliminating secondary safety hazards caused by reagent accumulation.

Furthermore, combined with special processes such as edge sealing reinforcement and anti-permeation coating, chemical resistant laminate can further enhance the protective capacity of furniture, forming a double guarantee with leak-proof trays and sealed cabinets to block the spread of risks. In addition, the edges and corners are rounded and polished to eliminate hidden dangers of collisions and scratches, making it suitable for various furniture parts such as workbenches and reagent cabinet panels. Ultimately, whether for high-frequency daily teaching experiments or complex working conditions of scientific research experiments, chemical resistant laminat can safeguard the safety of laboratory furniture with stable performance, becoming an indispensable barrier for experimental safety.

Feature

- Chemical resistant laminate boasts exceptional resistance to acids, alkalis, solvents and corrosives.

- Non-porous, dense surface prevents residue buildup,

- Easy to clean, meeting lab hygiene standards.

- Wear/impact-resistant,

- Customizable in size/thickness,

Chemical resistant Laminate specification

| Chemical resistant laminate | Good price |

|---|---|

| Feature | Big size |

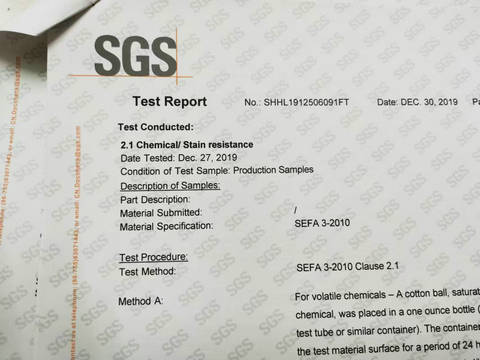

| Chemical resistance | SEFA3-2010 |

| Material | Phenolic resin |

| Type | Sheet |

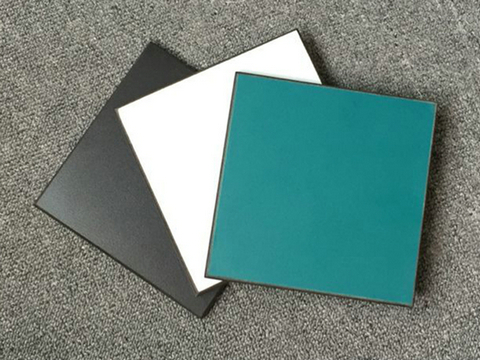

| Color | Black,Grey,White |

| Size (foot) | 5×12 |

| Size (mm) | 1525×3660 |

| Thickness(mm) | 12.7,16,19,25 |

| Surface finish | Matt |

| Density | 1.51 |

| Certificate | SGS |

| Mini order | 30 |

Colors

Chemical resistance

Certificate

The advance machine of chemical resistant laminate

Packing

Shipping

A professional chemical resistant laminate supplier

Looking for more…

Phenolic resin countertops

Grey epoxy countertops

Epoxy resin sinks