Fume hood phenolic worktops

- The fume hood phenolic worktops serve as the core carrier for experimental operations. As the core area for handling volatile, corrosive, or toxic substances, fume hoods require worktops that directly come into contact with various chemicals and experimental operations.

- The characteristics of phenolic resin worktops make them an ideal choice, widely used in chemical laboratories, biological laboratories, pharmaceutical research and development, and other scenarios, providing a safe and durable operational foundation for laboratory personnel.

- Compared with ordinary worktops, these specialized worktops can better complement the safety functions of fume hoods, reduce the risk of chemical leakage and experimental accidents caused by worktop damage, and extend the overall service life of fume hoods.

Analysis of core functions:

- The anti-spill design at the edges of the worktops is of vital importance. Marine edge can quickly intercept leaked liquid reagents, preventing them from seeping into the cabinet interior to corrode the structure or flowing onto the floor to cause slipping risks.

- Anti-permeation: A physical barrier is formed through the marine edge structure to block the path of liquid permeation into the cabinet, protecting the safety of the equipment structure.

- Anti-slip: Collect leaked liquid in time to reduce the hidden danger of slippery ground and improve the safety of the operating environment.

- Design logic:

- Using the principle of fluid mechanics, the marine edge form guides the liquid to flow to the designated collection area, realizing the protection chain of “interception – diversion – collection”. It is suitable for scenarios with strict anti-leakage requirements such as laboratories and chemical operation platforms.

- Meanwhile, the phenolic worktops need to efficiently integrate with the ventilation system: a smooth and level surface should ensure uniform airflow passage, preventing harmful gases from stagnating in the operation area.

- Additionally, anti-static and easy-to-clean features can reduce dust accumulation and electrostatic spark hazards.

- Combined with regular disinfection and maintenance, they further safeguard the experimental environment. From reagent pouring to high-temperature reactions, every detail of the worktop design aims to “block risks and protect safety,” making it the first line of defense in laboratory safety protection.

Phenolic resin countertops

Grey epoxy countertops

Epoxy resin sinks

fume hood tops Specifications

| Feature | Chemical resistance |

| Code | |

| Material | Phenolic resin |

| Type | Worktop |

| Size | Custom |

| Thickness | 4, 12.7, 16,19,25 |

| Color | Black, grey, white |

| Surface finish | Matt |

| Density | 1.51 |

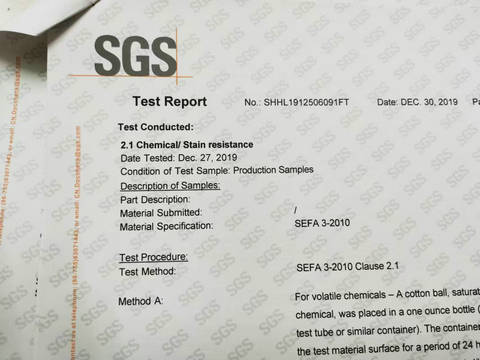

| Certificate | SEFA3-2010 |

| Mini order | 30 |

| Fabricating drawing | Requred |

Fume hood phenolic sheets

Phenolic marine edge worktops

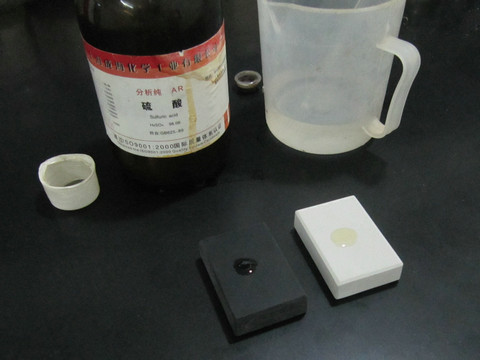

chemical resistance

SGS cretificate

Worktops fabricating

Worktops shipping

Professional fume hood countertopa supplier