chemical sinks

- Chemical sinks, vital in labs and industrial settings, often use pp or epoxy materials.

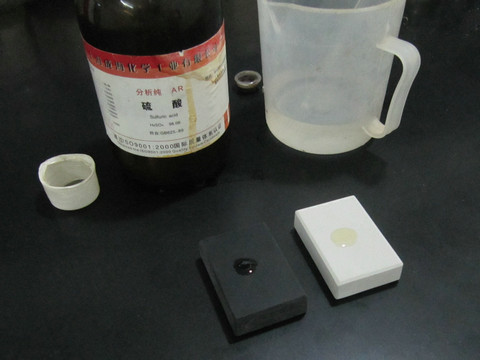

- PP sinks resist many chemicals and are budget-friendly. They handle mild acids and daily cleaning well. But they can get damaged by strong solvents or heavy impacts.

- Epoxy sinks are tougher. They stand up to harsh chemicals, high heat, and heavy use. Their seamless design stops leaks and makes cleaning easy. However, they cost more than phenolic ones.

- Choosing depends on needs. PP works for basic labs with light use. Epoxy is better for places with strong chemicals or heavy activity. Both keep sinks functional, but epoxy offers longer-lasting protection.

How does it work?

- Firstly, it is mainly used for cleaning laboratory apparatus. Beakers, flasks, test tubes, and other glassware or metal tools need to be thoroughly washed after experiments. The sink provides a convenient space for this process. Its material is carefully selected to withstand the chemicals used during cleaning. For example, some sinks are made of corrosion – resistant materials like pp to handle acidic or basic cleaning solutions.

- Secondly, it acts as a collection point for laboratory waste liquids. During experiments, various waste solutions are generated. The laboratory sink can temporarily hold these liquids before proper disposal. Some advanced sinks are equipped with filtering systems to separate solid particles from the waste, facilitating subsequent treatment.

- In terms of design, the chemical resistant sink usually has an efficient drainage system.

- The drain size is appropriate to allow quick removal of large amounts of liquid.

- There is often a strainer to prevent small parts of the apparatus or solid debris from clogging the drainpipe.

- The size and shape of the sink also vary.

- Larger sinks are suitable for bigger equipment or mass cleaning, while smaller ones are for delicate instruments.

- Additionally, some sinks may come with faucets for easy rinsing and racks or hooks for drying the apparatus after cleaning.

Application

Sink Specification

| Code | M356 |

| Material | Epoxy Resin |

| Type | Lipped sink |

| Color | Off White |

| Surface finish | Honed |

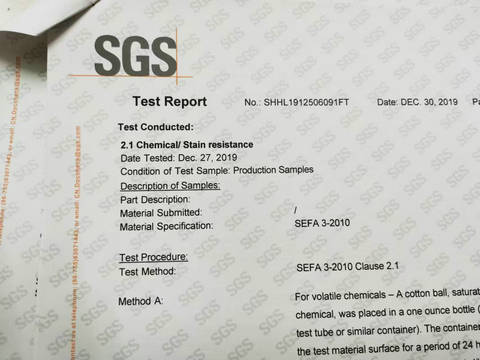

| SGS cetificate | SEFA3-2010 |

| Installation method | Drop in , Undermount |

| Inner size | 356x254x152 |

| Flange thickness | 8 |

| Application | University ,High school |

| Cost | M |

| Mini ordere | 30 |

Strong chemical resistance

SGS cretificate

Packing

Lab sinks supplier