corrosion resistant countertops

- When it comes to selecting corrosion resistant countertops for environments prone to chemical exposure, corrosion resistance is a non-negotiable factor.

- Among the top-performing materials, epoxy resin , phenolic resin, and ceramic stand out for their unique properties that make them ideal for labs, industrial facilities, and university

Epoxy countertops

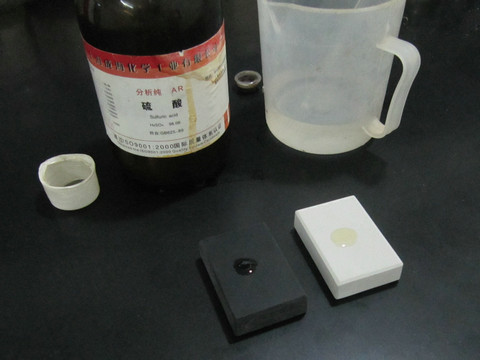

- It is celebrated for their seamless construction and exceptional chemical resistance.

- Made by blending epoxy resin with hardeners, these surfaces form a non-porous barrier that repels acids, solvents, and oils.

- This impermeability not only prevents corrosion but also makes them easy to clean and maintain, reducing the risk of bacterial growth.

- Epoxy’s versatility shines in custom applications—they can be tinted to match any color scheme and seamlessly integrated with sinks or backsplashes, making them a popular choice for both functional labs and modern commercial spaces.

Phenolic resin countertops

- It offer a lightweight yet durable alternative, particularly valued for their resistance to moderate chemical exposure and high temperatures.

- Composed of layers of phenolic resin-impregnated paper compressed under heat and pressure, they boast a tight, uniform structure that resists warping and cracking.

- Phenolic surfaces are cost-effective and well-suited for educational labs, healthcare facilities, and industrial workstations where frequent use and occasional chemical spills are common.

- Their matte finish minimizes glare, enhancing visibility for detailed tasks, while their inherent strength ensures long-term performance under heavy use.

Ceramic countertops

- It is the epitome of durability, combining heat resistance with unmatched resistance to corrosion.

- Crafted from fired clay infused with minerals, ceramic surfaces are non-reactive to most chemicals, including strong acids and alkalis. Their hard, glass-like finish repels stains and scratches, maintaining a pristine appearance even after years of harsh use.

- Ceramic is particularly favored in high-heat environments such as commercial kitchens and industrial settings where open flames or hot equipment are regularly used.

- Available in a range of textures and colors, from sleek polished to rustic matte, ceramic countertops blend functionality with aesthetic appeal, making them a timeless choice for demanding spaces.

Conclusion

Each of these materials—epoxy, phenolic, and ceramic—brings distinct advantages to corrosion-resistant countertops. Whether prioritizing chemical resistance, cost-effectiveness, or heat tolerance, these options ensure longevity and reliability in even the most challenging environments.

You choose phenolic vs epoxy ?, Fume hood phenolic worktops, Chemical resistance worktops

Acid resistant countertops, Chemical resistant worktops supplier

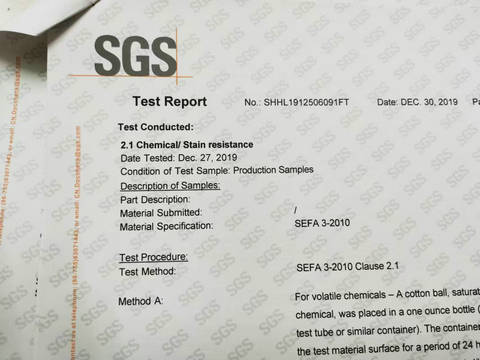

chemical resistance

SGS certifcate

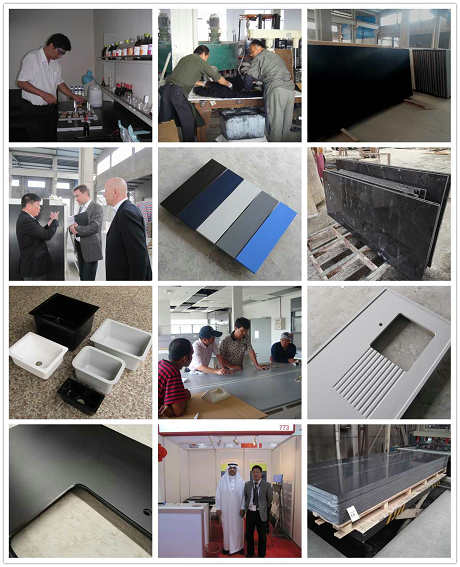

Professional Corrosion resistant worktops supplier