Epoxy Countertops pros and cons

It is of great importance for users of countertops to understand the epoxy countertops pros and cons.

Pros

Epoxy countertops have become a popular choice in high – end laboratories due to their outstanding performance. These countertops are formed by integrally casting and curing epoxy resin with quartz sand, creating a seamless and dense surface that effectively prevents bacterial growth and liquid penetration.

Meeting GMP standards, they are suitable for aseptic operations such as cell culture in the biopharmaceutical field.

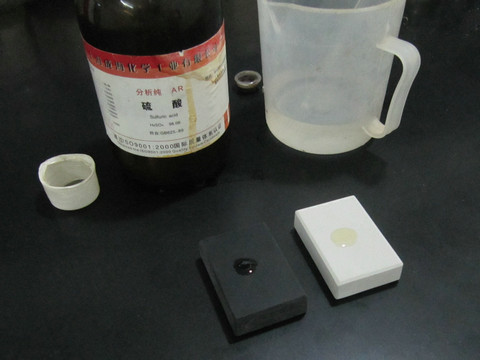

Their exceptional corrosion resistance is particularly remarkable, as they can withstand highly corrosive reagents like 98% concentrated sulfuric acid and aqua regia.

In chemical synthesis laboratories, they remain undamaged even after long – term exposure to solvents such as dichloromethane and concentrated nitric acid.

Additionally, they can endure long – term high temperatures of up to 180°C and withstand 200°C locally for short periods, allowing heating equipment to be placed on them without any issues.

With a Mohs hardness of 3 – 4, regular laboratory utensils rarely leave scratches, and their service life can extend up to 15 – 20 years.

Cons

After understanding the epoxy pros and cons, when faced with the cons, We also deeply feel the same way.

They come with a high price tag, approximately two to three times that of phenolic countertops, which greatly increases upfront investment.

Their high density makes them about 1.5 times heavier than ordinary countertops, resulting in difficult installation and transportation.

Moreover, repair work is complex when damaged. Professional personnel are required to mix resin for filling, sanding, and polishing to fix local scratches or damages, which is costly and time – consuming.

Therefore, epoxy countertops are more suitable for scientific research, pharmaceutical, and chemical laboratories with extremely high performance requirements and sufficient budgets.

Slab Specification

| Application | Laboratory countertops |

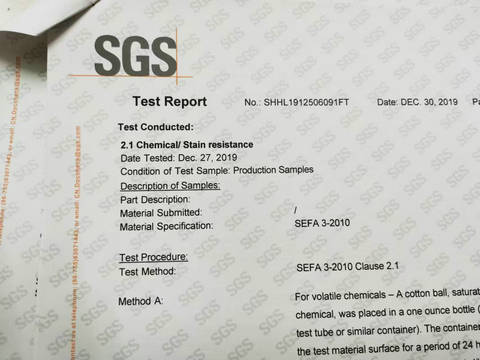

| Certificate | SEFA3-2010 |

| Material | Epoxy Resin |

| Size | 3200×1600 |

| Thickness | 12.7,16,19,25 |

| Color | Black,Grey,White |

| Surface finish | Honed |

| Density | 2.3 |

| Mini order | 30 |

High-Temperature Resistance:

chemical resistance

SGS certifcate

a Professional Epoxy slabs supplier