epoxy marine edges

Notably, Epoxy marine edges are a premium sealing solution for lab worktops, engineered for harsh, moisture-rich and chemical-exposed lab environments. Moreover, molded integrally with epoxy resin worktops, they form a seamless, gap-free bond that blocks liquid penetration, water seepage and bacterial buildup—vital for lab sink zones, wet workstations and chemical handling areas where leakage risks are high.

Specifically, crafted from high-grade epoxy resin with high-temperature curing, these sealed edges deliver outstanding water resistance, acid-alkali and solvent tolerance. They withstand constant water contact, heavy impacts and daily scuffs without delamination, warping or discoloration. Additionally, rounded corner finishes enhance operational safety, preventing sharp-edge injuries during routine lab operations.

Furthermore, low-maintenance by design, this lab worktop sealing solution only needs cleaning with water or neutral detergent, no frequent re-sealing required. It extends the worktop’s overall service life, ultimately making epoxy marine edges a durable, cost-effective choice for professional laboratory settings.

Epoxy marine edges Overall Adaptability and Design Positioning

Notably, Epoxy marine edges are a premium sealing solution for lab worktops, engineered specifically for harsh, moisture-rich and chemical-exposed lab environments. Meanwhile, chemical laboratories have extremely high requirements for worktops, which need to withstand continuous corrosive chemical exposure, frequent water contact and high-intensity usage wear. Essentially, epoxy resin countertops paired with epoxy marine edges perfectly meet these stringent demands, serving as an integrated sealing solution for high-risk areas that eliminates structural weak points of traditional worktops, thereby providing uncompromising durability and safety for chemical testing, synthesis and wet processing operations. Furthermore, this design’s seamless integration also lays a solid foundation for long-term lab operational stability.

Molding Process and Sealing Performance

Primarily, Epoxy marine edges are integrally molded with epoxy resin countertop bodies via high-temperature curing technology, forming a 100% seamless, joint-free structure that completely blocks liquid penetration. Specifically, this seamless bond prevents corrosive acid-alkali leaks, solvent splashes and water seepage from penetrating the substrate, effectively avoiding countertop delamination, material aging and hidden bacterial growth. Furthermore, this feature is particularly critical for lab sink surrounds, chemical dispensing zones and continuous wet operation areas where leakage risks are high; additionally, the high-purity epoxy composition of the entire bonded structure ensures uniform performance across the worktop, thereby reinforcing overall reliability.

Multi-Dimensional Resistance and Safety Optimization

Crafted from high-grade epoxy resin, this integral design initially endows epoxy marine edges with excellent physical and chemical resistance. They withstand strong acid, alkali and organic solvent erosion without discoloration or damage, and furthermore endure heavy impacts, daily scuffs and repeated cleaning without chipping or warping. Additionally, rounded corner finishes on epoxy marine edges eliminate sharp edges, reducing scratch risks during fast-paced lab work. Moreover, the consistent thermal expansion coefficient of the epoxy structure prevents cracking from temperature fluctuations caused by hot plates, water baths and other equipment, while meanwhile enhancing long-term stability under frequent environmental changes.

Maintenance Advantages and Application Value

Low-maintenance by design, epoxy marine edges only require cleaning with water or neutral detergent, with no frequent resealing needed. Furthermore, they significantly extend the overall service life of epoxy resin countertops, reducing laboratory maintenance costs and downtime. In summary, this solution complies with global laboratory safety and hygiene standards, making epoxy marine edges a durable, cost-effective choice for professional chemical research labs, analytical testing institutions and educational chemistry laboratories.

edges Specifications

| Epoxy marine edges | Blocking chemical waste water for lab countertop |

|---|---|

| Feature | Chemical resistant, many size ,easy installation |

| Material | Epoxy resin |

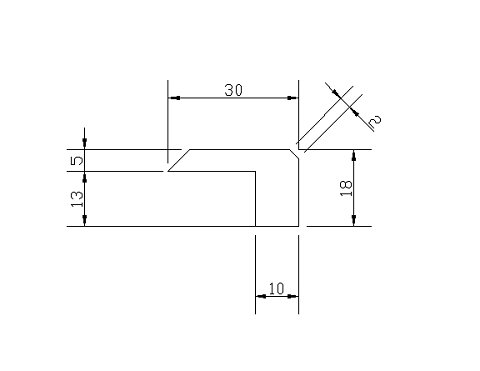

| Type1 | EDG12.7 |

| Size | 3200/18/30 |

| Application | Designed for 12.7 mm thick phenolic resin boards, solving the water blocking problem of the phenolic laminate countertop |

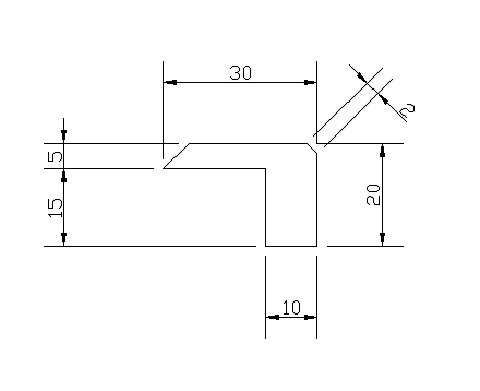

| Type2 | EDG20 |

| Size | 3200×25/30 |

| Application | Suitable for edge sealing and water blocking of phenolic laminate boards, epoxy boards and ceramic boards with a thickness of 20 mm. |

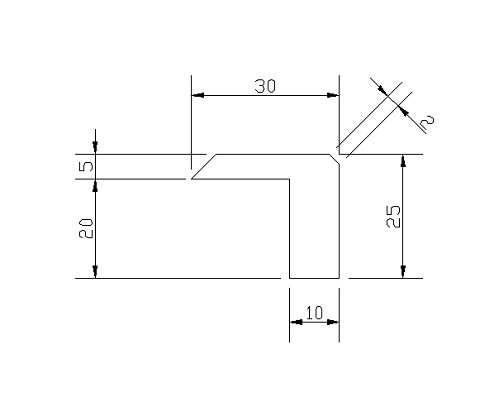

| Type3 | EDG15 |

| Size | 3200×20/30 |

| Application | Suitable for edge sealing and water blocking of phenolic laminate boards, epoxy boards and ceramic boards with a thickness of 15 mm |

| Colors | Black,Grey, White |

| Height of the raised part for water retaining | 5 MM |

| MOQ | 30 PCS |

Edges section samples

Epoxy marine edges application

Edge section details

Epoxy resin marine edges

Marine edge countertops project for Saudi Arabia

Strong chemical resistance

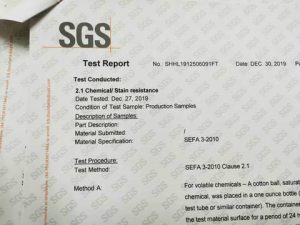

SGS certificate

Packing

a professional epoxy marine edges supplier