Chemical resistant HPL

- Chemical resistant HPL (High-Pressure Laminate) is a crucial material for educational institutions. First, this includes universities, where science labs frequently handle various chemicals during advanced experiments. Additionally, middle schools, which introduce students to basic chemical processes, rely on it to withstand routine spills and cleaning. Moreover, primary schools, though using milder substances, benefit from its durability to endure daily wear and tear from young learners. In short, across all levels of education, HPL ensures long-lasting, safe surfaces that support hands-on learning without compromising on functionality.

- In university research labs, it withstands harsh chemicals used in advanced experiments, ensuring long – lasting durability and safety.

- Its seamless surface prevents chemical penetration, protecting students and faculty from potential hazards.

- In middle and primary schools, where hands – on science experiments are common, HPL offers an affordable yet reliable solution.

- It resists stains and scratches from everyday use, maintaining a clean and professional appearance.

- Teachers can confidently guide students through experiments without worrying about damage to the work surfaces.

- Cost – effective and easy to maintain, HPL provides a safe and functional environment for learning across all educational levels.

hPL specifications

| Feature | Chemical resistant and cost effective |

| Trade name | Chemical resistant laminate |

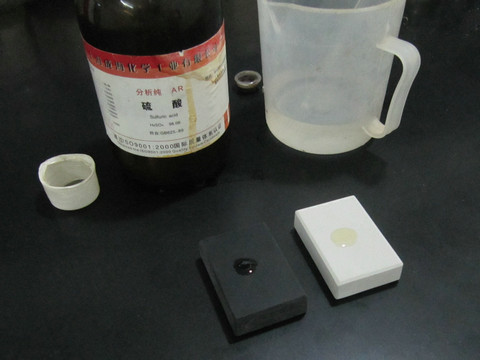

| Chemical resistance | SEFA3-2010 |

| Material | Phenolic resin |

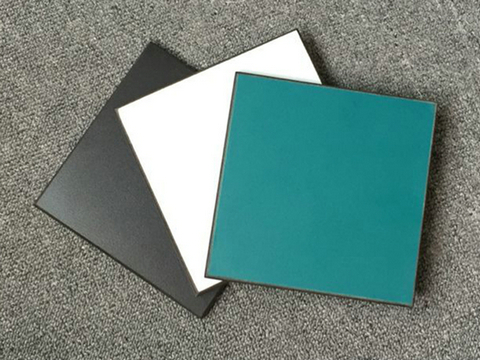

| Color | Black,Grey,White |

| Size (foot) | 5×12 |

| Size (mm) | 1525×3660 |

| Thickness(mm) | 12.7,16,19,25 |

| Surface finish | Matt |

| Density | 1.5 |

| Certificate | SGS |

| Mini order | 30 |

High pressure machine for HPL

Chemical resistant testing

Certifications

Stock hPL sheets

HPLsheets loading

Professional chemical resistant hPL supplier