laboratory epoxy countertops

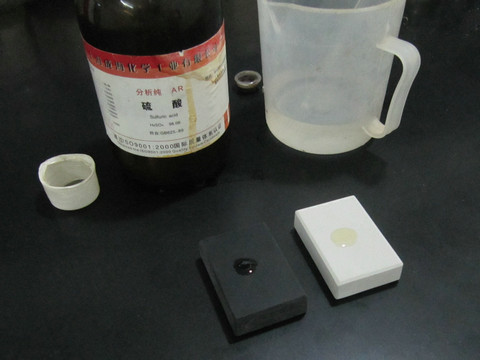

Laboratory epoxy countertops with high temperature resistance are professional lab surfaces for heat-intensive scenarios, specifically crafted from modified high-performance epoxy resin via seamless one-piece molding. Infused with special heat-resistant additives, their formula is further upgraded for extreme thermal stability, thus enabling them to withstand continuous high temperatures and short-term thermal shocks from lab heat treatment. They neither deform nor discolor under routine heating operations, nor develop surface cracks, perfectly suiting high-heat experiment and sample processing work.

Meanwhile, these countertops still retain premium chemical resistance, effectively standing up to acids, alkalis and solvents, and their seamless structure firmly blocks chemical leakage to ensure lab safety. Additionally, the non-porous surface is both scratch and impact-proof, and it is easily sanitized—simply wipe with disinfectant to meet sterile standards. Widely available in customizable sizes and thicknesses, they well fit material, metallurgy and chemical labs. Ultimately, they are both sturdy and low-maintenance, reliably delivering stable performance under high-temperature, high-frequency lab use.

Countertops Specification

| Laboratory epoxy countertop | Heat resistance |

|---|---|

| Material | Epoxy Resin |

| Type | Countertops,Worktops |

| Size | Custom |

| Thickness | 12.7,16,19, 25 |

| Color | Black,grey,white |

| Surface finish | Honed |

| Density | 2.3 |

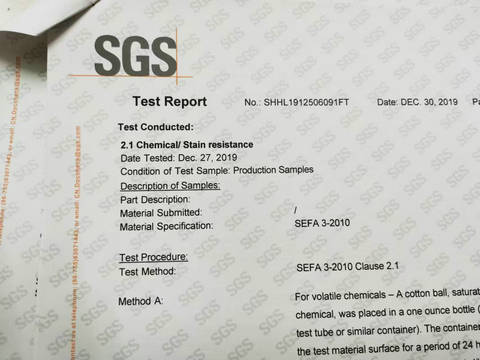

| SGS certificate | SEFA3-2010 |

| Mini order | 30 |

| Fabricating drawing | Requred |

Feature

In specialized labs, such as those conducting materials synthesis or combustion studies, epoxy countertops can endure higher intermittent temperatures. Even when paired with heat-resistant pads, they can reliably handle brief exposure to 250°C (482°F), thus accommodating tasks like annealing small samples or working with molten substances. This versatility in turn eliminates the need for frequent surface replacements, ultimately lowering long-term maintenance costs.

Chemical resistance

certificate

International Shipping

A Professional Laboratory epoxy countertop supplier

Looking for more