Heavy duty epoxy lab slabs

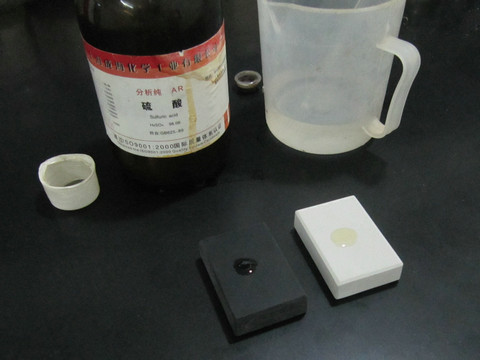

Heavy Duty Epoxy Lab Slabs, crafted with high-strength composite technology, are specifically designed for high-load laboratory environments. Their acid resistance and scratch resistance set the benchmark for laboratory safety protection. These slabs are made by pressing epoxy resin and medium-grained quartz sand, featuring a dense and stable molecular structure. They can withstand long-term exposure to highly corrosive reagents such as hydrochloric acid, nitric acid, and hydrofluoric acid. Even when directly in contact with 37% concentrated hydrochloric acid or 65% concentrated nitric acid, the surface will not swell, discolor, or suffer structural damage, fundamentally eliminating the risk of chemical leakage.

In terms of scratch resistance, the surface of the slabs forms a hardened protective layer with quartz, reaching a Mohs hardness of over 6. This enables them to resist frequent scratches from tweezers, test tube clamps, and other utensils, and even withstand the impact of falling glassware without permanent scratches. This characteristic not only ensures that the surface remains smooth and clean over time, preventing stains from accumulating and bacteria from breeding, but also prevents reagent residues from hiding in scratches and causing cross-contamination. Whether it is the dropping of strong acids in organic synthesis experiments or the collisions of utensils in inorganic analysis, epoxy lab slabs provide a robust and reliable safety platform for laboratory operations with their excellent physical and chemical stability.

Heavy duty slabs Specification

| Heavy duty epoxy lab sheets | Heavy duty epoxy lab boards |

|---|---|

| Code | |

| Material | Epoxy resin |

| Type | Slab |

| Size | 3200×1600 |

| Thickness | 16,19,25 |

| Color | Black, Grey |

| Surface finish | Honed |

| Density | 2.3 |

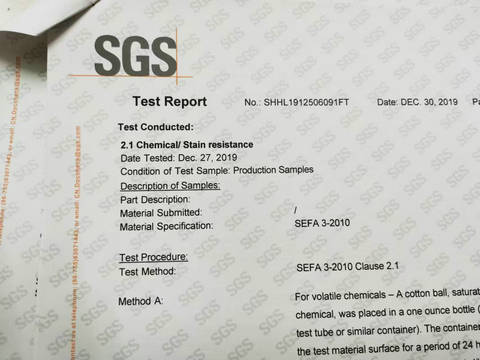

| Certificate | SEFA3-2010 |

| Mini order | 30 |

Heavy duty epoxy countertops appllication

chemical resistance

SES certificate

Professional heavy duty slabs supplier