Phenolic Resin Board:

In laboratory settings, phenolic resin board are widely used due to their excellent chemical stability, heat resistance, and mechanical strength.

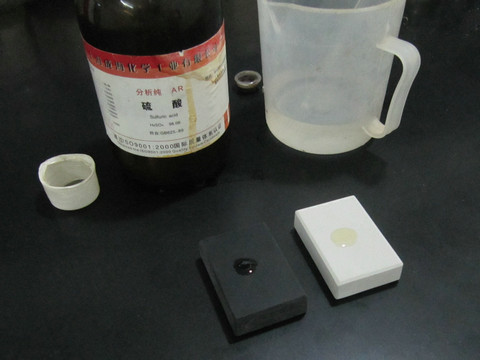

Their remarkable resistance to acids, alkalis, and organic solvents makes them ideal for manufacturing laboratory countertops and fume hood linings, effectively withstanding corrosion from strong acids (such as sulfuric acid and nitric acid) and alkalis (like sodium hydroxide) to extend equipment service life.

The material demonstrates significant heat resistance, maintaining structural stability without deformation below 150°C (e.g., near ovens or muffle furnaces), thus suitable as thermal insulation pads or high-temperature experimental supports.

Its smooth and dense surface is easy to clean and anti-pollution, making it suitable for building operation platforms for microbial culture, chemical synthesis, and other experiments.

Additionally, phenolic boards exhibit good electrical insulation, serving as insulating partitions in electrical experiments (such as circuit construction or resistance testing) to ensure operational safety.

With high mechanical strength, they can bear the weight of conventional laboratory instruments. Note that prolonged exposure to strong oxidants or ultraviolet rays may cause material aging, so rational selection based on the experimental environment is necessary.

Phenolic resin countertops

Grey epoxy countertops

Epoxy resin sinks

Phenolic tops

Pros and cons of phenolic countertops

Black epoxy lab slabs

Acid resistant countertops

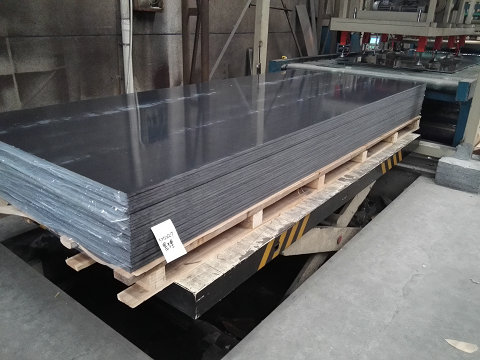

Phenolic boards specifications

| Feature | Cost and chemical resistance |

| Trade name | Chemical resistant laminate |

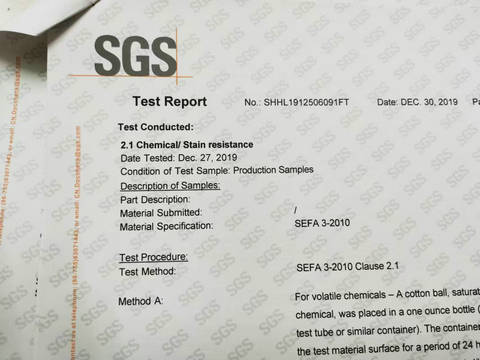

| Chemical resistance | SEFA3-2010 |

| Material | Phenolic resin |

| Color | Black,Grey,White |

| Size (foot) | 5×12 |

| Size (mm) | 1525×3660 |

| Thickness(mm) | 12.7,16,19,25 |

| Surface finish | Matt |

| Density | 1.5 |

| Certificate | SGS |

| Mini order | 30 |

Boards Chemical resistanc

Certificate

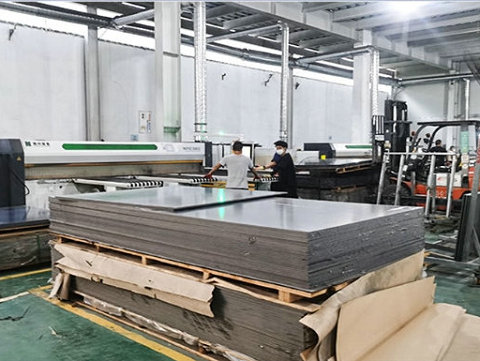

Countertop fabricating

Shipping

A professional phenolic resin sheets suppllier