acid resistant countertops

Acid resistant countertops are made of epoxy resin and mineral filler. According to different applications, epoxy resin is modified to improve its ability to resist industrial strong acids such as sulfuric acid. The principle of modification is as ,Epoxy resin undergoes a cross-linking reaction with curing agents such as amines or anhydrides , forming a highly dense three-dimensional network macromolecular structure.This structure contains virtually no micropores or gaps, effectively blocking the penetration of acidic molecules (such as H⁺, SO₄²⁻, Cl⁻, etc.) and preventing acid from contacting the substrate internally, thereby avoiding corrosion.

Feature

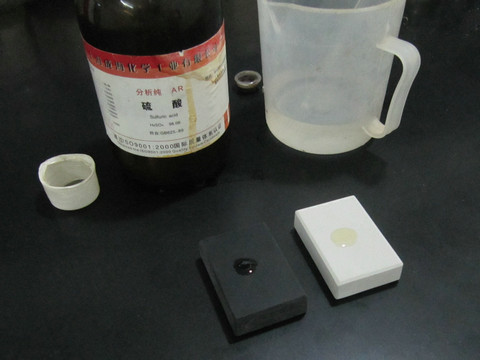

- Resists 90% concentrated sulfuric acid — no structural damage to the countertop surface even in a concentrated sulfuric acid environment.

- Super-hard silicon filler enhances the countertop’s hardness, scratch resistance, and service life.

- Highly repairable — fix damaged countertops effortlessly with our dedicated repair kit.

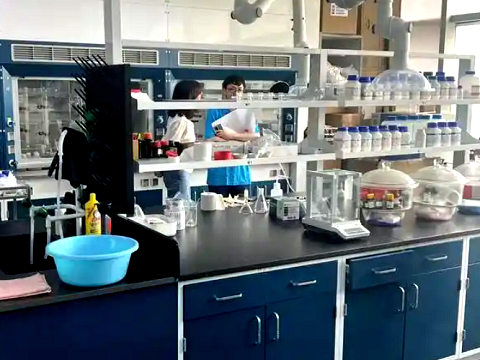

Applications of Concentrated Sulfuric Acid in Organic Chemistry Laboratories

In organic chemistry laboratories, concentrated sulfuric acid is a core reagent that functions as both a catalyst and a dehydrating agent, and it is indispensable in various types of synthesis reactions. It can catalyze the dehydration of ethanol to prepare ethylene and promote the substitution reaction between benzene and nitric acid to synthesize nitrobenzene. In esterification reactions, it can not only accelerate the reaction rate but also absorb the generated water to drive the equilibrium to shift forward, thereby increasing the yield of esters. Additionally, it is a key reagent in sulfonation reactions, enabling the introduction of sulfonic acid groups into benzene rings to prepare aromatic compounds with better water solubility.

Extreme caution is required during use: operations must be conducted in a fume hood, and the principle of “adding acid to water” must be strictly followed when diluting; contact with organic substances and reducing agents should be avoided to prevent hazards; instruments should be cleaned promptly after experiments to prevent residual acid from corroding the equipment.

Countertops specification

| Acid resistant countertops | Organic chemistry laboratories |

|---|---|

| Feature | Chemical resistance |

| Material | Mondificate epoxy resin |

| Type | Countertop |

| Size | As required |

| Thickness | 19 |

| Color | Black |

| Surface finish | Honed |

| Density | 2.35 |

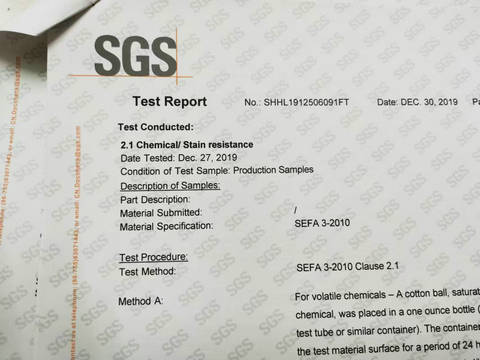

| SGS certificate | SEFA3-2010 |

| Fabricating drawing | Requred |

Application

SGS cretificate

Shipping

Professional Acid resistant worktops supplier