phenolic vs epoxy

- Phenolic Vs Epoxy; Phenolic and epoxy countertops are top options. They each have unique performance traits. But they are different. This makes choosing between them tricky.Countertops are more than just functional surfaces in commercial and industrial design. They are critical components. They need to balance durability, chemical resistance and practicality. This helps them meet the needs of their environment.

- Countertops are used in many places. These include laboratories, healthcare facilities, commercial kitchens and industrial workshops. The choice of countertop material matters a lot. It affects how long the countertops last. It also affects maintenance costs. And it impacts how well operations run.

- In the realm of commercial and industrial design, countertops serve as more than just functional surfaces—they are critical components that must balance durability, chemical resistance, and practicality to meet the demands of their environment. Whether in laboratories, healthcare facilities, commercial kitchens, or industrial workshops, the choice of countertop material directly impacts longevity, maintenance costs, and operational efficiency. Among the leading options, phenolic and epoxy countertops stand out for their unique blends of performance traits, yet their differences often make selection a nuanced decision.

Analysis of Key Scenario Adaptability

- Educational/Elementary and Secondary School Laboratories

- Phenolic is Superior: Meets the requirements of basic acid – base experiments (such as pH testing and simple titration). With low cost and convenient maintenance, it is suitable for scenarios where students conduct frequent operations.

- Example: In a middle school physics laboratory, when placing common instruments like balances and beakers, the impact resistance of phenolic countertops can withstand minor collisions.

- University Research/Chemical Synthesis Laboratories

- Epoxy is Superior: When dealing with highly corrosive reagents such as concentrated nitric acid and toluene, the full – surface corrosion resistance of epoxy countertops can prevent damage and reduce the risk of contamination.

- Example: In organic synthesis experiments, epoxy countertops can directly come into contact with solvents like diethyl ether and dichloromethane without penetration or deformation during long – term use.

- Biological/Medical Laboratories

- Epoxy is Superior: The seamless surface prevents bacteria from hiding, and it supports moist heat sterilization (such as autoclaving at 121°C) and chemical disinfection (such as sodium hypochlorite), meeting GMP/ISO 17025 standards.

- Limitations of Phenolic: The micro – porous structure may retain culture media or cell suspensions. Inadequate cleaning can easily lead to contamination, making it unsuitable for aseptic operations (such as cell culture).

- High – Temperature/Physics Laboratories

- Epoxy is Superior: Heating plates (≤180°C) and muffle furnaces (with heat – insulating pads) can be directly placed on it. Phenolic countertops may release formaldehyde or crack when exposed to high temperatures.

Long – Term Cost and Maintenance Comparison

- Phenolic Countertops: Low initial investment, but need to be replaced within 5 – 8 years (due to surface wear or corrosion), with an average annual cost of about $8 – $12 per linear foot; require regular wiping with neutral detergents to avoid scratch accumulation.

- Epoxy Countertops: High initial cost, but with a lifespan of 15 – 20 years, and an average annual cost of about $20 – $30 per linear foot; easy to maintain , with higher long – term cost – effectiveness.

Core Performance Comparison

- Choose Phenolic Countertops: When the budget is limited, the experimental intensity is low, and operations are mainly basic (such as in primary and secondary schools, community laboratories).

- Choose Epoxy Countertops: When high durability is required, or when dealing with highly corrosive/high – temperature environments, or when strict hygiene requirements exist (such as in pharmaceutical factories, environmental testing centers).

Note: If the laboratory involves radioactive substances or biosafety levels P3/P4, stainless steel or special ceramic countertops should be prioritized, and ventilation system design should be considered.

Phenolic resin countertops

Grey epoxy countertops

Epoxy resin sinks

Certifications

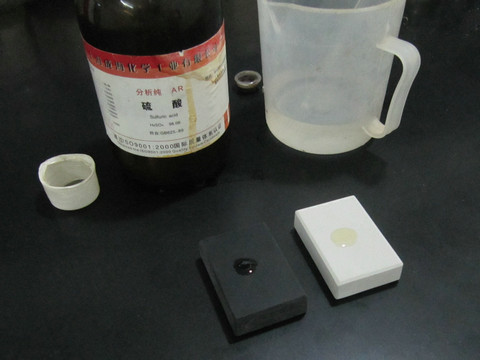

Chemical resistance testing

Phenolic resin countertops fabricating

Epoxy resin countertops fabricating

Countertops shipping

Professional phenolic countertops supplier